|

|

APPLICATION ARTICLES

When someone contacts me for Fluid Power Training, their first priority is how to troubleshoot their hydraulic systems.

Unfortunately, from my 35 years experience, its not that easy, to be proficient at troubleshooting they first need to understand the basic function of Fluid Power components. For my customers who ask me for troubleshooting help, my first question, do you have a schematic? Without a schematic it is extremely difficult if not impossible (large manifold with slip-in cartridges) to determine first and second steps in the troubleshooting process. That is why I recommend, rather then teaching a troubleshooting class, why not incorporate troubleshooting, while teaching the identification of symbols and the basic function of each component in a hydraulic system.

Unfortunately, from my 35 years experience, its not that easy, to be proficient at troubleshooting they first need to understand the basic function of Fluid Power components. For my customers who ask me for troubleshooting help, my first question, do you have a schematic? Without a schematic it is extremely difficult if not impossible (large manifold with slip-in cartridges) to determine first and second steps in the troubleshooting process. That is why I recommend, rather then teaching a troubleshooting class, why not incorporate troubleshooting, while teaching the identification of symbols and the basic function of each component in a hydraulic system.Once my students get comfortable with symbols and components, which takes about 2 days, itts time to put circuits on a hydraulic training simulator. I let the students put a circuit (maybe a sequence valve and pressure reducing valve simulating press and drill circuit), that I have drawn on a erasable board, onto one of my Hydraulic Trainers, and then let the fun begin.

As so often happens, the training mimics real life troubleshooting situations. The first thing that typically happens is the students who work together is teams of 4 start connecting hoses, and usually they over connect and do not pay attention to the schematic. This goes on for a while until I help them focus on the schematic as compared to the connections on the valves. Once the students realize that everyone has moved the hoses many times and still the system doesnnt work, they finally go through a systematic approach and verify that all the hose connections are in correct placement.

Now back to trouble shooting, the students who have verified the circuit is connected properly, panic because the circuit still doesnnt work. This is where the understanding of the circuit is handy, since they have placed two pressure valves in the circuit it is necessary to adjust them to the circuit drawings pressure settings. And they soon find out that it is necessary to have a lot of gauges and a flow meter is nice to. And some valves like SUN Mfg. adjust pressure higher by turning them counter-clockwise versus what you normally would think clockwise. So troubleshooting a system has to be done in a systematic approach while following pressure settings dictated by original designer. This is no different then replacing pressure relief, sequence, counterbalance, reducing valves on hydraulic systems in the field. Once they are replaced they also have to be adjusted back to original design specifications.

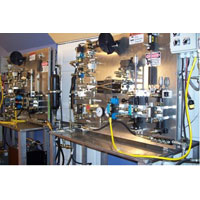

Hydraulic Trainer Equipment

I might add that pressure valves, such as sequence, counterbalance, relief, braking valve, look very similar as a symbol. What determines which valve it is, is often determined by where it is in a circuit and how it is being used. For further information on training FluidPowerTraining.net

<- Back to Application Articles